About Company

VS Aircontrols, established in 2012, is a leading manufacturer of aluminium scaffolding and duct lifting solutions. We specialize in the sales and renting of lightweight, high-strength aluminium scaffolding and duct lifters, supporting safe height access and lifting requirements for various industries.

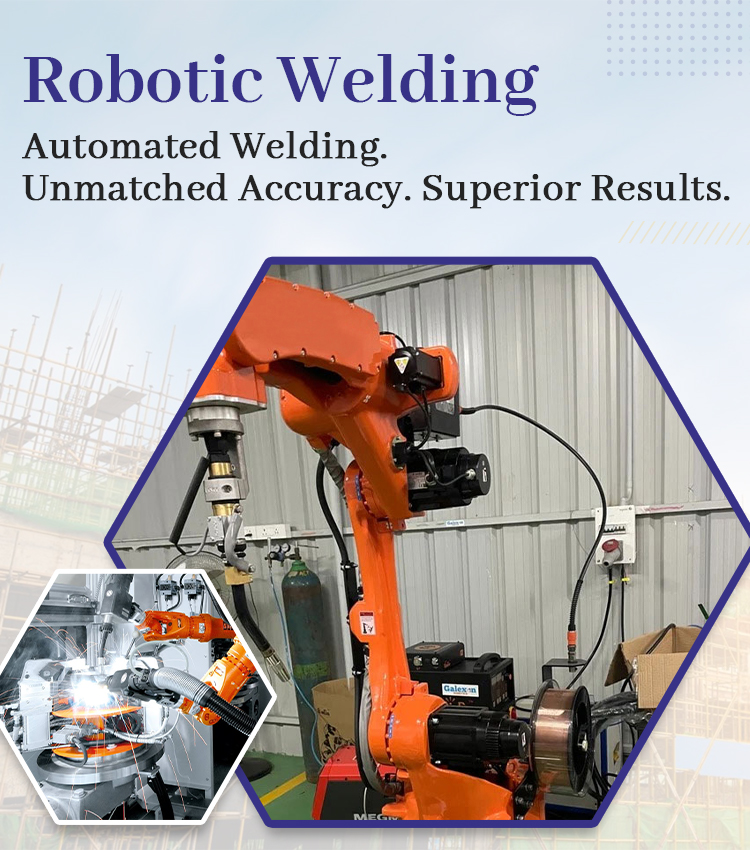

At VS Aircontrols, we take pride in using advanced robotic welding technology for all our aluminium scaffolding systems. This provides us with a significant advantage over traditional fabrication methods and ensures our clients receive world-class quality, safety, and reliability.

- Fully automated robotic welding ensures precision, consistency, and stronger welds in every joint, eliminating manual errors and delivering superior structural integrity.

- Deep fusion welds offer better load-bearing capacity and safety, which is critical for working at heights.

- Premium-grade finish: clean, uniform, spatter-free joints reduce the need for polishing, providing excellent aesthetics and quality.

- Faster production, faster delivery: robotics increase our production speed by up to 3x, helping us meet tight deadlines with ease.

- Zero compromise on safety: every scaffold is welded with robotic accuracy, reducing the risk of weak joints or failures.

- High-accuracy welding: ideal for thin-walled aluminium tubes, ladders, frames, and cross braces, ensuring perfect fit and alignment.

- Export-ready quality: our robotic process ensures products meet global standards for quality, safety, and finish.

- Professionalism & reliability: investing in robotic welding reflects our commitment to innovation and long-term client satisfaction.

Our Products

You Step Up - We Keep It Safe

Manufacturer, Sales & Rental of Aluminium Scaffoldings, Aluminium Ladders, & Duct Lifters

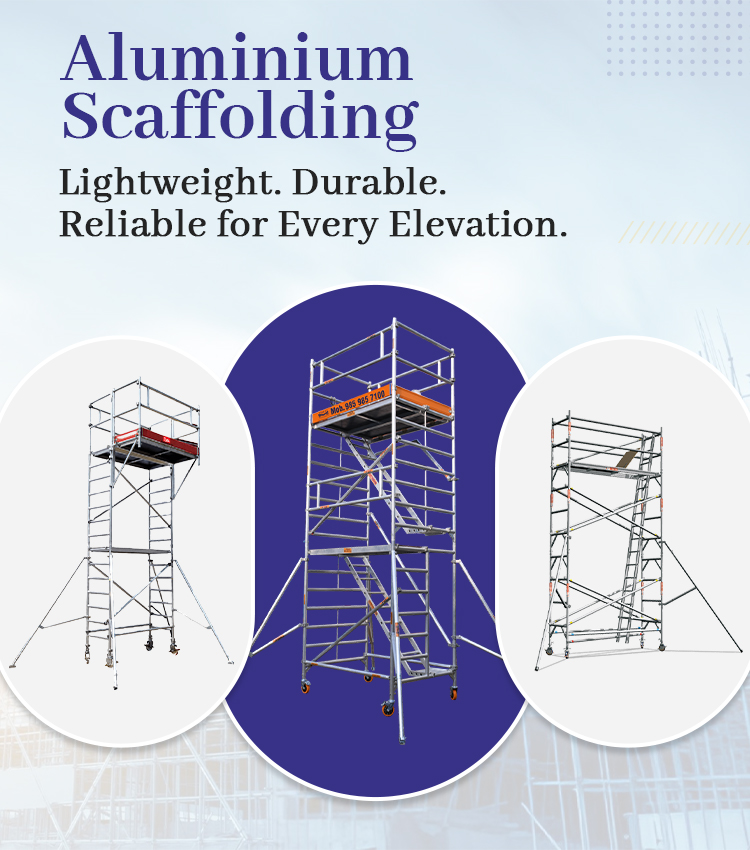

Aluminium Scaffolding

Dimension: 0.75m x 1.8m / Height Range: 1m - 6m

Dimension: 1.35m x 1.8m / Height Range: 1m - 12m

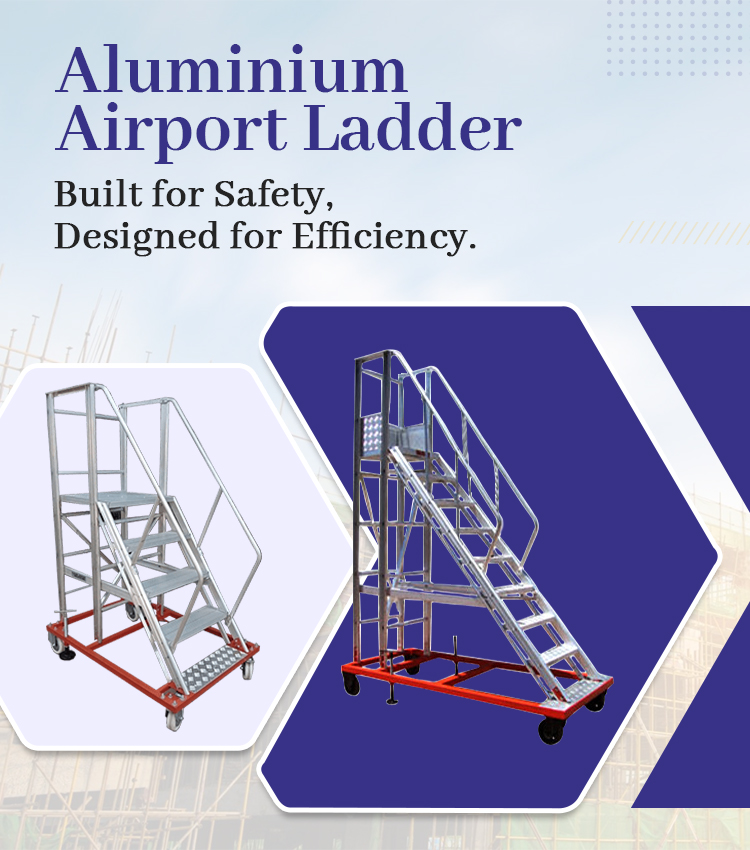

Aluminium Airport Ladder

Height: 4 ft up to 20 ft

Step Size: 24" x 7" | Platform Size: 24" x 24"

Maximum Worked Load: 250 kg | Wheel Size: 6x2 nylon

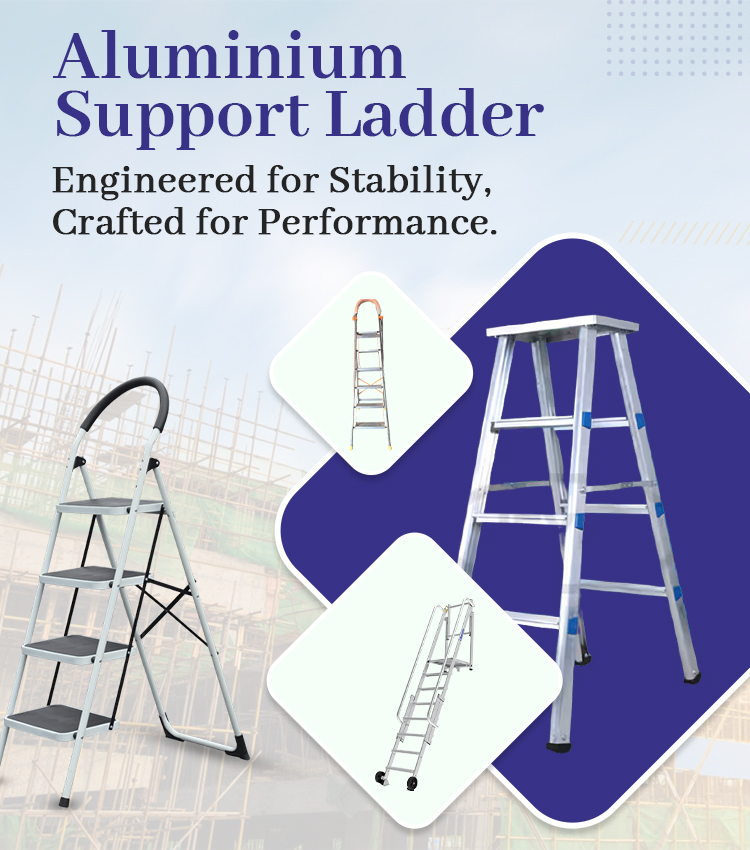

Aluminium Support Ladder

Height: 4 ft up to 20 ft

Maximum Worked Load: 100 kg | Bottom Rubber Shoe

Desk Surfer Ladders

Maximum Safe Working Load: 125 kg

Castor Lockable Wheels | Height Adjustable Platform

Suitable for Indoor Use

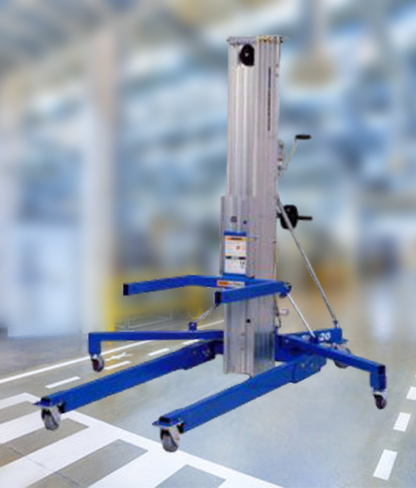

Duct Lifters

Compact and durable lifters with strong load capacity, adjustable height, and easy mobility for installation and maintenance tasks.

Inquire for Rent / SaleLatest Projects

Explore our gallery showcasing a wide range of products and projects. Each image reflects the quality, precision and reliability , we consistently deliver to our customers.

Our Projects